Nathan Stanley

School of Chemical Engineering

Faculty of Sciences, Engineering and Technology

Eligible to supervise Masters and PhD (as Co-Supervisor) - email supervisor to discuss availability.

Dr Nathan Stanley is a research & development scientist with diverse professional experience including the application of synthetic organic chemistry to the creation of small molecules as therapeutics and experimental tools, peptide chemistry, food chemistry, additive manufacturing composites and inks formulation, sensor electronics and air purification technology development.

Nathan obtained his undergraduate degree in Synthetic Chemistry and Pharmacology from The University of Adelaide in 2004 before continuing on and achieving First Class Honours in Pharmacology in 2005. Following this he endeavoured to combine his passion for chemistry and phamacology by undertaking a PhD in Medicinal Chemistry, also at The University of Adelaide. After being awarded his PhD he spent two years on a postdoctoral appointment at The University of Otago, New Zealand. He then moved to Orléans, France in 2013, where he joined the Protein Synthesis & Glycoengineering Group at the Centre de Biophysique Moléculaire division of the Centre National de la Recherche Scientifique (CNRS). Now based in Adelaide, his skills and expertise are applied to research projects within the ARC Graphene Research Hub under the direction of Professor Dusan Losic.

Thriving in a collaborative research environment, he believes academic and industrial linkages are key to real future innovation. His additional skills and experience include chemical engineering, pharmacology, biochemistry, electronics and computer-aided design.

He is currently working in partnership with ASX-listed company Archer Materials Ltd to develop new biosensor devices for point of care medical diagnostics. This work was recently highlighted in ECMS Connect:

https://ecms.adelaide.edu.au/news/list/2020/11/03/adelaide-researchers-graphene-biosensing-device

We Believe in Revolutionizing the Face of Healthcare

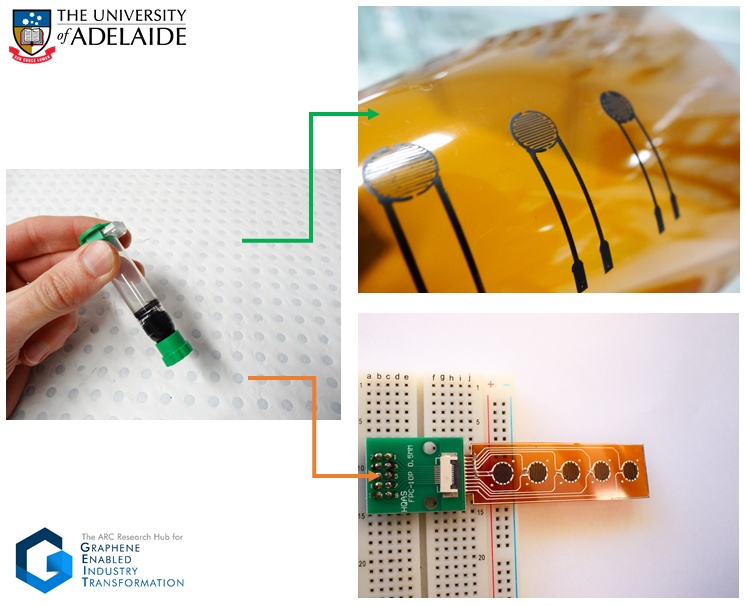

In partnership with Archer Materials Ltd. our team is developing a biosensing platform for point-of-care medical diagnostics. At the heart of our technology is functionalized graphene, an electro-active material capable of single-molecule detection of key biomarkers related to infection and disease. Archer’s graphene carbon material is synthesized from sustainable precursors including ethanol and sodium obtained from sea salt. The sensors we are creating are fully printed using digital and scalable technologies, enabling future automation and lower production costs. Our biosensing platform aims to make health care more accessible and affordable for all.

Our Research is Enabling Printable, Flexible Sensor Technologies

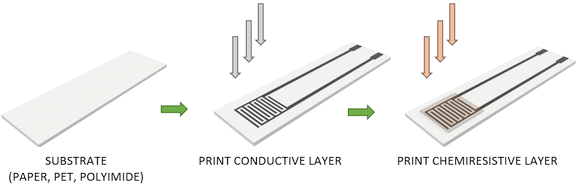

One major focus of our research is the preparation of functionalized printable inks based on graphene and other 2D materials. This technology allows us to create printed sensing devices. To be practical and commercially viable, new sensors need to meet key criteria such as low cost, minimal size, high sensitivity, suitable selectivity and offer low environmental impact construction. These thin, flexible sensors will soon find application in consumer devices from smartphones and wearables to drones to biomedical, food and environmental monitoring. We're capitalizing on digital printing technologies such as ink extrusion (direct ink writing) and inkjet materials printing. Additive, direct-to-substrate printing of conductive (graphene, carbon nanotubes, MXenes, silver) and chemi-receptive functionalized layers can be used to build up sensing elements on bio-degradable paper and thin polymer films, enabling rapid prototyping of new sensors in a tightly controlled and inexpensive manner.

Multi-layer direct-to-substrate printing of chemiresistive sensing elements

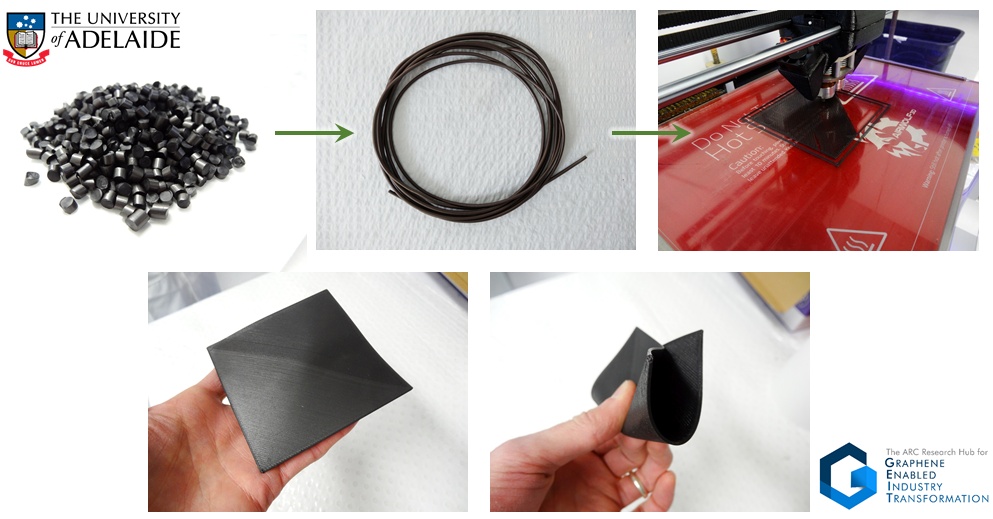

We're Developing the Materials of Tomorrow

Additive manufacturing is becoming indispensable as a fabrication and prototyping tool in key sectors including aerospace, automotive, biomedical and defence. Fused filament fabrication (3D printing) is a primary technology in this ecosystem which relies on thermoplastic polymers as base material. The enhancement of features such as mechanical strength, durability, UV resistance, thermal stability and electrical conductivity can be achieved by design and formulation of new composite materials that can be applied directly to 3D printing of digitally designed structures. These new materials have already been shown to be useful in applications as diverse as EMI shielding, footwear, lightweight prosthetics and flexible strain sensors. We’re creating 3D-printable polymer composite materials enhanced with nano- and 2D materials including graphene, carbon nanotubes (CNT), molybdenum disulfide (MoS2), hexagonal boron nitride (h-BN) and MXenes.

-

Language Competencies

Language Competency French Can read and write -

Education

Date Institution name Country Title 2006 - 2010 University of Adelaide, Adelaide Australia PhD 2005 - 2005 University of Adelaide Australia Honours (Pharmacology) -

Research Interests

-

Journals

-

Conference Items

Year Citation 2014 Stanley, N. J., Aucagne, V., & Delmas, A. (2014). N-Terminal Linkers for Solid Phase Peptide Ligation. Poster session presented at the meeting of 33rd European Peptide Symposium. Sofia, Bulgaria. -

Patents

Year Citation 2017 Sammut, I. A., Harrison, J. C., Hewitt, R. J., Read, M. I., Stanley, N. J., Woods, L. M., . . . Larsen, D. S. (2017). 62/261,072, Carbon Monoxide Releasing Norbornenone Compounds. United States of America. 2017 Sammut, I. A., Harrison, J. C., Hewitt, R. J., Read, M. I., Stanley, N. J., Woods, L. M., . . . Larsen, D. S. (2017). 62/261,072, Carbon Monoxide Releasing Norbornenone Compounds. United States of America. -

Theses

Year Citation 2010 Stanley, N. J. (2010). Synthesis of Glutamate Mimics as Neuropathic Pain Modulating Agents. (PhD Thesis, The University of Adelaide).

|

2017 |

South Australian Early Commercialisation Funding |

|

|

SUCCESSFUL |

|

|

Development of Fumigant Capture and Recycling Technologies |

|

2017 |

South Australian Grain Industry Trust Funding |

|

|

Development of new processes for scrubbing and recovery of sulfuryl fluoride grain protectant |

|

2016 |

Ramsay Fellowship Candidate, University of Adelaide |

|

|

Exploration of marine natural product scaffolds towards next generation anti-malarial and anti-cancer agents |

|

2015 |

DECRA Candidate, University of Adelaide |

|

|

Chemical synthesis of unique marine natural product scaffolds |

-

Current Higher Degree by Research Supervision (University of Adelaide)

Date Role Research Topic Program Degree Type Student Load Student Name 2022 Co-Supervisor Harnessing Light–Matter Interactions in Nanoporous Photonic Crystal Structures for Gas Sensing Doctor of Philosophy Doctorate Full Time Mr Khoa Tran -

Other Supervision Activities

Date Role Research Topic Location Program Supervision Type Student Load Student Name 2020 - 2020 Principal Supervisor Formulation and Extrusion of 2D Graphene and MXene Polymer Composites for 3D Printing The University of Adelaide Chemical Engineering and Advanced Materials Honours Part Time Quan Huynh 2019 - 2019 Principal Supervisor 3D-Printable Flexible Graphene Composites The University of Adelaide Research Intern Other Part Time Daniel O'Connor 2018 - ongoing Principal Supervisor Development of Graphene-based Printed Gas Sensors on Flexible Substrates The University of Adelaide Chemical Engineering Honours Part Time Le Hong An Nguyen 2016 - 2016 Principal Supervisor Influence of Atmospheric Cold Plasma Treatment on Whole Grain Flour Enzymes Lipoxygenase and Peroxidase The University of Adelaide Chemical Engineering Honours Part Time Demi Vlass

Connect With Me

External Profiles